If you looking to buy the new mixer machine then you need to surly read this whole article about the concrete mixer machine. It will clearly give you the idea of what exactly is your need. What types & capacity mixer machine I need to obtain my target work & the last one which is the Concrete mixer manufacturers are there who provide the best quality mixer at the best price.

After reading this whole page you might be clear with your decision what exactly your decision if you are going to really purchase the Concrete mixer machine.

Concrete Mixer Machine name itself tells you that a kind of mixer machine is there. Which is going to be mixes the all material for concreting purpose according to your requirement. It also called the Cement Mixer machine.

A concrete mixer mixes the cement, gravel, sand, water, and provides you the concreting material. Which you can use it for your construction purpose. Mixer can do varieties of work from small projects to one big large scale site project. You need at least any of one mixer machine. It may be any kind of as per your requirement.

First, we will let you know about the main three types of concrete mixers available in the market.

Types of Concrete Mixer Machine

1. Stationary Mixer Machine

Stationary types of machines are the most common among the civil contractor and used for used project work. Where you have enough time and work for small quantities of work. This kind of mixer price is cheap as compared to any of the other varieties.

The stationary machine gets fixed at one place for certain distance work. In that radius you can do your work.

You can also tell the batch mixer machine. Where ever you required the work 50 Cub to 70 Cub work in whole day then it should be your preferences and yes along with that you also required the manpower to fill the bucket of mixer. Even for discharge & concrete filling purpose also you may need the man power.

So that if your small project work then it may suitable with manpower costing. In Stationary Concrete mixer also some different kind of varieties is there.

a. Hand Feed Mixer

In hand feed mixer machine whole material of concreting need to feed by manually directly inside the drum. It is the cheapest mixer machine but its disadvantage is that you need to pour the material at heighted drum that required more man power as compared to others.

In these types, material quantity is uncertain how much material you have poured inside the drum. It also not as efficient as others are. The main disadvantage is you don’t know how much water you mixed with the material. So material came out from the mixer is low quality.

b. Hydraulic Cement Mixer Machine

Hydraulic Cement Mixer Machine enabled with the hopper and hydraulic system. In this you do not require to fill the drum at a heightened place. You just need to fill the material in hopper and hopper will move all material through the hydraulic system into the drum. By tilting the drum it will discharge the material on the other side.

C. Concrete Mixer enabled with digital Meter

A concrete mixer can also be enabled with the digital meter that gives you an idea of the kind of material you have made inside the machine. Different kinds of structures need the different kinds of concrete mix ratio that digital meter will brief you. The concreting process will be the same as the above mixer had.

d. Reversible Cement concrete mixer

In reversible cement concrete mixer you can pour the material from one side in bins that digitally enabled and other side materials get discharge according to your requirement of mix ratio.

In the type of mixer range, a reversible mixer is costly as compared to the above one because it required low manpower and digitally enables gives the varieties of mixtures.

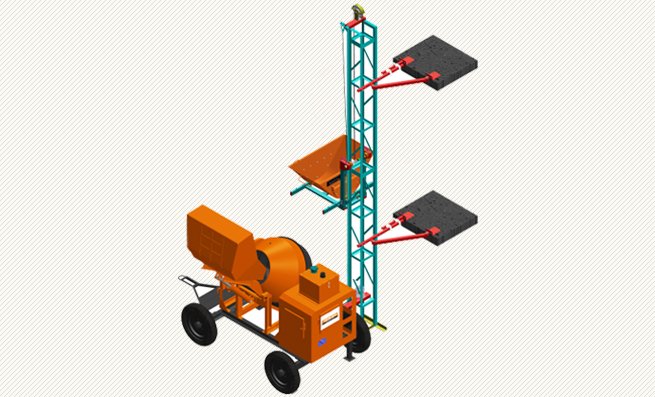

d. Concrete Mixer Machine with Lift

Concrete mixer with lift is the same as stationary mixer machine in this just lift add on for lift material up to the required building floor. Concrete mixer with lift has a dual advantage with one motor engine and lift both works can be done.

This will available with the hopper and without hopper.

2. Mobile Concrete Mixer (Self Loading Concrete Mixer Truck)

Self-loading concrete mixer is automated, saving manpower and equipped with feeding hopper that automatically takes the material according to requirement mix it in drum and discharges it where ever required it on site.

SLM (Self Loading Mixer) is current time most running product for concerting. The medium-scale project that required complete work in less time with less manpower with efficient and quality material.

Self-loading mixer is the ideal choice for construction of cemented road, cannel, factories, boundary walls, and small bridges.

3. Concrete Batching Plant

A concrete batching plant used for the bigger site wherever the project goes on 1-2 years and more. It used in Shopping malls, bridges, highways, airports, heightened buildings. A concrete batching plant is the batch plant is equipment that combines with various ingredients to form concrete.

Silos, hopper, mixture, conveyor, batcher, weighting system make full batching plant. It provides high-quality material with a high quantity of discharge facilities. Batching plants also available in stationary and mobile versions. Choose wisely what fulfill your need.

Concrete Mixer Machine Price

Concrete Mixer price depends on the kind of features available in the Machine. Many types are mixer machines are available as you have seen above. Diesel Engine, Electric Engine, Hydraulic, manual, and many more options are there. Even many companies provide personalized mixer according to requirements.

Price of Concrete Mixer Machine

| Types of Mixer | In USA | In India |

|---|---|---|

| Small Lower Price Mixer | $175 USD | 35,000 INR |

| Medium Range Capacity mixer | $15000 USD | 4,50,000 INR |

| Self Loading Mixer truck | $90,000 USD | 32,00,000 INR |

Different countries have a different price structure. You may import the machine from low-cost making mixer countries like India, China. Batching plant and self-loading mixer price will be different than the normal. Batching Plant price is not given it can only be finalized when you let them know your exact requirement.

Concrete Mixer Machine Capacity

1. Small Concrete Mixer capacity lies in between 0.20 Cubic Meter to 0.8 Cubic Meter.

2. While Self loading Concrete mixer Capacity lies in between 1.0 Cubic to 5 Cubic.

3. Batching plants capacity start from 15 Cubic Meter and goes up to the 160 Cubic Meter.

Different manufacturers provide different varieties & capacity machine according to customer need. Batching plant is the highest capacity producer of concrete material.

Concrete Mixer Machine Manufacturers

All over the world more than 10000 mixer manufacturers are there all have their own capacity to supply. Their own country has a niche demand as per their requirement. Like in India, China & South African countries are the highest users of the small stationary kind of concrete mixer machine.

While batching plant and self-loading concrete mixers are used almost in all countries from developed nations to underdeveloped countries.

We let you know the some of the branded manufacturer in batching plant and Self loading concrete mixer.

List of Concrete Mixer Machine Manufacturer

Batching Plant Brands – Schwing Stetter, Sany, Putzmeister, linnhoff, liebherr.

Normal Small Concrete Mixer Machine Manufacturer – None of the international brans is there in Small Concrete mixer Machine. Every Country has its mechanical company they manufacturer the normal cement mixer.

Self Loading Concrete Mixer – Fiori, Schwing Stetter, Ajax, Carmix, Aimix are some the international brands apart from this many local brands are available with respective countries.

This all about the concrete mixer machine we have told you. Now you might have an idea what is your decision according to your requirement and in the budget also.

Let us know your view in comment section.

You’ll also like to read

This site was… how do I say it? Relevant!! Finally I have found something that helped me. Thanks a lot!