In the market, various kind of crusher plant is there and used in different industries for fulfilling the crushing needs but here we will talk all about the stone crusher plant. How stone crusher plant is working, what are the stone crusher machine is available in the market. Types of stone crusher plant available and kind of requirement plant fulfilled.

Earlier crushing plant is one-stop installation activities but nowadays as requirement changes, stone crusher plant technology, design, input, output, capacity changed. International brands continuously updating their product with technology, digitization, and artificial intelligence.

Let’s clear what stone crusher plant actually does.

“Stone crusher plant is a machine designed to reduce the large stone, granites, marble, lime rocks into the smaller size and output gravel, dust, different size of the material.”

Stone crusher plants used worldwide. It is available with different-2 capacity, design, and utility.

Uses of Crusher plant

Stone crushing industry engaged in producing a crushed stone that used as a raw material for infrastructure projects like, road, highway, bridges, building canals, etc. All projects are considered as the core infrastructure work that gives the economy boom.

Stone crusher units are not alone. Along with these plants, stone mining also associated. In fact, stone mining is the primary activity, and the crushing plant is the secondary activity that can be considered.

Raw materials used for crushing unit

Coal, Stone, Granite, limestone, Basalt, River stone, andesite calcite, abrasive rocks, glass, and ferrous material used for the crushing purpose.

Stone Crusher plant Capacity

The stone crusher plant will available from 50 TPH to 600 TPH (ton per hour). The plant can produce the 8 variants of material. Just to get the different variant material you also need to put the screening plant that just separates the different materials according to client or market demand.

Stone Crusher plant works

Raw Material processed through the vibrating feeder to crusher gradually and crusher crushed the material into respective pieces. From Crusher material conveyed to belt conveyor for secondary crushing before went on vibrating screen plant. Vibrating screen plant separates the quality and qualified material to final products.

And unqualified material carried back to stone crusher and reprocesses it. Then again material went through the above process. The customer gets the required material according to the standard quality and different sizes.

At last dust generated during the whole process that needs to control by different equipment.

Types of Stone Crusher plant

Crushing plants make use of a large range of equipment that makes the full stone crushing plant. It consists of the screener, feeder, loading, unloading, conveyor, hopper, separator, crusher.

The main important part of the whole plant is the crusher. Other equipment totally depends on that. All the other supported equipment will be fitted according to the crusher plant capacity.

To get the fine product from the crusher. We need to pass it through three types of crushers in stage-wise. First Primary Crusher in that direct material comes from mines. Secondary crusher process the primary crusher material that already crushed at material size reduced and tertiary crusher which reduces the material size further. The manufacturer gets the desired size. That can be further supply to users.

Types of plant we divided into two types first according to design and second according to utility.

| Types by design and utility | Jaw Crusher | Cone Crusher | Imact Crusher |

|---|---|---|---|

| Mobile Crusher Plant | Availbale | Availbale | Availbale |

| Stationary Crusher Plant | Availbale | Availbale | Availbale |

| Portable Crusher Plant | Available | Availbale | Availbale |

Jaw Crusher

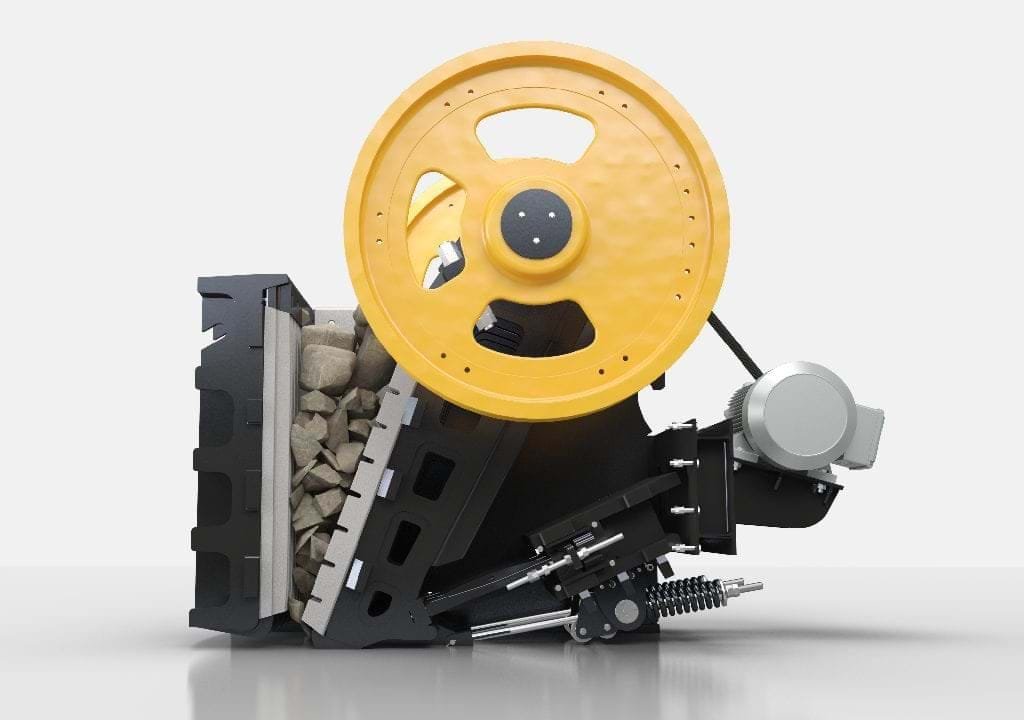

A jaw crusher is the compression kind of crusher and used for crushing rock between two heavy steel jaws. The movable jaw compresses the material against the fixed jaw and crushes material at the desired size. Material exits from the bottom of jaws.

Jaw crusher adjustable up to certain results. You may change the size as you want the output and bottom frame adjusted.

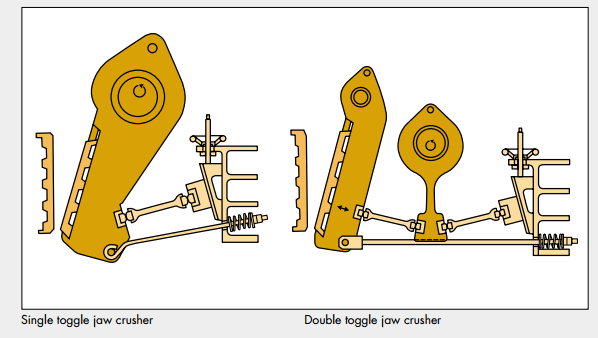

In stationary kind of crusher plant, jaw crusher installation is the highest. In jaw crusher two variants is available first, single toggle Jaw Crusher and second double toggle jaw crusher.

Double toggle jaw crusher is heavier and lots of moving parts than the single toggle jaw crusher. The main difference is the position of eccentric between both of them. Jaw crusher available in three variant mobile, stationary, and portable design whatever customer suits and full fills there need may consider it.

Cone Crusher

Cone Crusher also called a gyratory crusher. Cone crusher also a compression kind of machine that reduces, squeezing, or compressing the material between a moving piece of steel and a stationary piece of steel. The material passed it through the bottom of the machine after passed the cavity.

Why we called cone crusher because inside the crusher cone design piece of steel is there. That cone design pallet crushes the material.

The material gets in the feeder from the upper side and material output from the bottom. Cone crusher generally delivers the material 4:1 or 6:1 ratio. The below picture will clear more you about the Cone crusher.

Cone crushers can be available in a stationary, mobile and portable design. Whatever the design and material need suits you need to buy that.

Roller Crusher

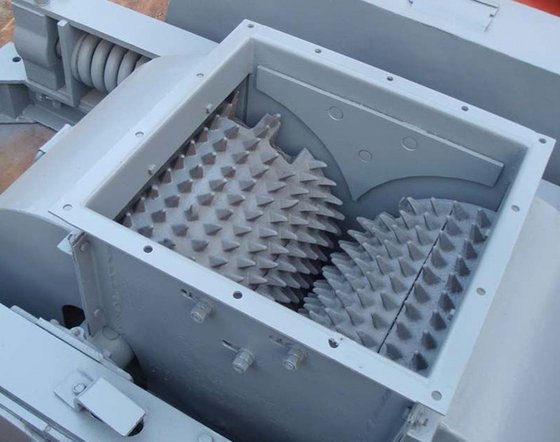

“Roller crusher breaks the material by squeezing it between two revolving metal cylinders that axes parallel to each other and separated according to required results.”

It consists the two opposite direction driven cylinders that mounted on horizontal shafts. The gap between the both cylinders can be adjusted according to desired results. Generally both cylinders cover with the manganese steel liners.

The Roller crusher ratio is lower as compared to the other crusher machine. The reduction ration of roller crusher is 2.5:1. Roller crusher not recommended for the abrasive kind material.

There is two kinds of roller crusher 1, Double roll crusher. 2, Single roll crusher. Name itself clears you both work. In double roller two cylinders are set up while in single roller crusher only has a cylinder that move at one place attached with horizontal shaft and material grind between the cylinder and inside body.

In Stone crusher generally, double crusher machine fitted. wherever material is soft as compared to stone their single roller crusher can be used.

Impact Crusher

Impact crusher is process the material by compression & force between two surfaces towards one another to crush the material caught between them. Material contain in the chamber that open according to desired result from bottom.

There are two kind of Impact Crusher

Horizontal shaft impact crusher (HSI Crushers)

In the chamber, shaft putted in horizontal way and HSI crushers known for high reduction ratios, especially when processing soft and medium hard materials.

Vertical Shaft impact crusher (VSI Crushers)

Vertical Shaft Impact Crusher is generally used in the last phase. VSI looks like a cone crusher from outside but working style different in both of them. In vertical shaft crusher, shaft putted in vertical way.

These are all the crusher types used for stone crushing. According to your product need you may choose the crusher and of course other factor are there which affects the decision making.

Criteria of Stone Crusher plant selection

Production Requirement – What actually production requirement you have. Many a time companies setup the plant especially for specific projects only. So you need to consider your whole project requirement.

Or if you are setup for supply of local construction demand then you should look the demand of your production material.

Ore Characteristics – Material you want to crush or output you want. That really impacts your decision like if you need the fine product then you may go for the roller crusher. So according to need of material you need to setup the plant.

Operational Considerations – Operational consideration means you might have constraint in operation like location. Location might be the operational constraint or labour constraint. Plant may near to your mining that reduce your transpiration cost but you may not allow doing so.

Capital Cost – Different brand, capacity, types of crusher impact on capital investment that also you need to consider. Which crusher will be in my budget and full fill my requirement.

These all about the Stone crusher plant. You may comment on your views.